Manufactured over 100 various Machinery Products

Project Description

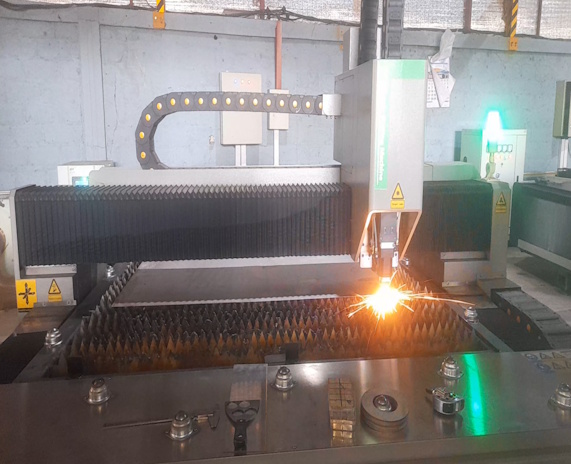

We successfully undertook the manufacturing of a wide variety of machinery parts required for tea factories and rice mills. These included customized components such as conveyors, hoppers, shafts, rollers, casings, and structural parts, all produced with precision to match the operational requirements of different factories. Every part was engineered to provide durability, improve efficiency, and reduce the frequency of breakdowns that disrupt production. Special care was taken to ensure proper sizing, neat finishing, and minimal cutting, making the manufactured items easy to install and reliable in performance.

A highlight of our work was the manufacturing of a bucket elevator at Giragama Tea Factory. This project, along with several others, reflected our expertise in creating tailored solutions for factories and mills. These were only a few of our many completed manufacturing projects, where we combined technical knowledge with high-quality materials to deliver machinery parts that enhanced productivity, minimized downtime, and extended equipment lifespan. Each manufactured item was also painted and finished professionally, ensuring both strength and a neat appearance.

The Challenge in Installation

One of the primary challenges during these projects was adapting new machinery parts to existing factory setups. Many factories operated with old or mixed-brand equipment, which made compatibility a key concern. Our team had to carefully measure and design each part to integrate seamlessly with the machinery, often customizing the structure to avoid unnecessary modifications. This required precision engineering and detailed planning at every stage of the process.

Another challenge was balancing customization with quick delivery. Since both tea factories and rice mills depended heavily on their machinery, extended downtime was not an option. We had to manage the manufacturing and installation phases under tight schedules while still ensuring high-quality standards. Despite these challenges, every project was completed on time and delivered lasting performance improvements.

"Our factory required a new bucket elevator as the existing system was no longer efficient for daily operations. The team manufactured the elevator to exact specifications and ensured that every detail, from the structure to the finishing, was handled with care. The installation was completed quickly, and the new unit has worked flawlessly since."

Factory Owner, Giragama Tea Factory, Kandy

The Final View of Project

At the conclusion of these projects, the newly manufactured machinery parts delivered strong improvements in both performance and reliability. The conveyors and hoppers helped streamline the handling of raw materials, while the bucket elevators significantly improved material movement within the factories. Each component was built to withstand heavy-duty use, ensuring long-term durability and reduced maintenance needs.